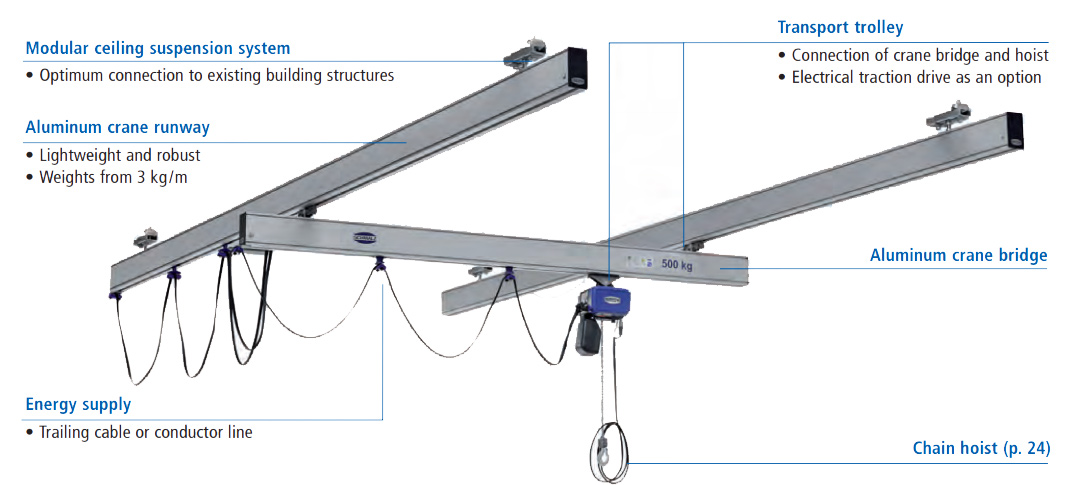

Gantry Cranes

Application

- Flexible modular system for the assembly of individual crane solutions

- Used in nearly all in-house handling and logistics processes.

Your Benefits

- Increased productivity thanks to reduced handling and loading times

- Secure, damage-free gripping by using vacuum

- Minimization of downtime due to employee injury

- Increase in employee motivation

- Only one person for handling

Design and Function

We have drawn on all of our experience and expertise as system manufacturers to create our Schmalz crane systems.

Thanks to their consistently lightweight design, they are the perfect addition to your vacuum tube lifter Jumbo or vacuum lifting device VacuMaster.

Whether as a jib crane or a crane system, the Schmalz modular system enables perfect integration into your working environment.

Even as a stand-alone solution, the modern crane system provides numerous advantages for your benefit.

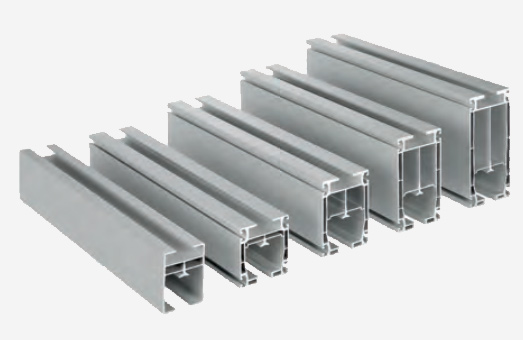

Lightweight and Robust Aluminum Section

- Weight optimized extruded section with hollow chamber geometry (weight from 3 kg/m)

- Inner web for reinforced vertical support

- Material: Aluminum natural anodized (EN AW 60 63 T66)

- Five section sizes for loads weighing up to 1,200 kg

- Section lengths up to 8,000 mm can be extended as

- needed using rail connectors

- Dovetail for retroactive mounting of variable end stops

- Lateral grooves for connecting accessories

- Weight optimized extruded section with hollow chamber geometry (weight from 3 kg/m)

- Inner web for reinforced vertical support

- Material: Aluminum natural anodized (EN AW 60 63 T66)

- Five section sizes for loads weighing up to 1,200 kg

- Section lengths up to 8,000 mm can be extended as

- needed using rail connectors

- Dovetail for retroactive mounting of variable end stops

- Lateral grooves for connecting accessories

Gantry System Components

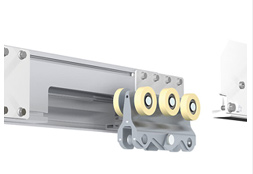

Transport Trolley

Stable aluminium pressure cast construction for loads weighing up to 1,000 kg

End Plate

- Attractive closing off of sections

- Protection from dirt

Rail Connector

- Positive and non positive connection of sections for crane runways or bridges larger than 8,000 mm

- Full load capacity at the interface

Crane Bridge Suspension Element

- Maximum load 2,000 kg

- Swivel mounted as standard

- Easy replacement of the joint

- 90° design for standard crane bridge; 0° design for telescopic rails

Fixed End Stops

- Prevents transport trolleys from falling out

- Positive locking for maximum safety

- Tool free mounting

Variable End Stops

- Easy adjustment of the crane bridge and hoist travel path

- Demarcation of several working

- Areas and the cable storage device

- Can be mounted at a later stage

Antishock End Stops

Gentle stopping of transport trolleys if end stops have to be reached e.g. for dynamic applications and telescopic jibs

Distance Connectors

- Reinforcement for the design of double bridge crane systems

- Available for all section sizes

Service Station

- Easy replacement of transport trolleys, particularly for long crane systems and for crane systems with several crane bridges

- Available for all section sizes

- Fully resilient depending on the section size

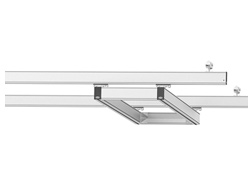

Low Headroom Module

- Raises crane bridge to the level of the crane runway

- Reduces the overall height of crane systems for low ceiling heights or transit roads

Spring Return for Telescopic Jib

Returns telescopic jibs after reaching into difficult to access areas. Optimal work flow thanks to the independent return of the jib.

Curved Radii

- Creation of true running monorails

- Suitable for radii greater than 2,000 mm

- Available for section SRA-180

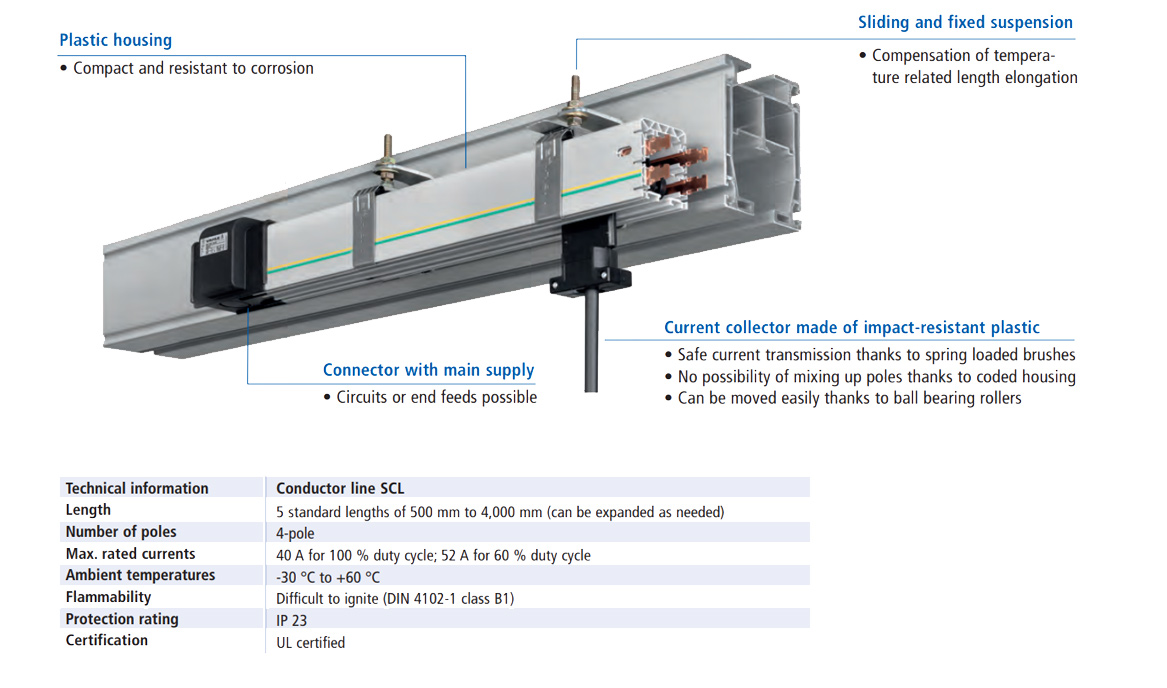

Conductor Line

- Wireless energy supply for electrical devices supplied in the crane such as the chain hoist or vacuum lifting device

- Profit from usable ceiling height as there are no cable storage devices or cable loops to cause interference

- Ideal for crane systems with several bridges

- Low surplus loading of the crane system thanks to lightweight plastic rails

- Easy mounting thanks to adapted suspensions and spring loaded connectors for copper contacts